WHO: Construction responsible for 39% of air pollution

Construction is also responsible for 36% of global electricity consumption and 1/3 of global drinking water consumption.

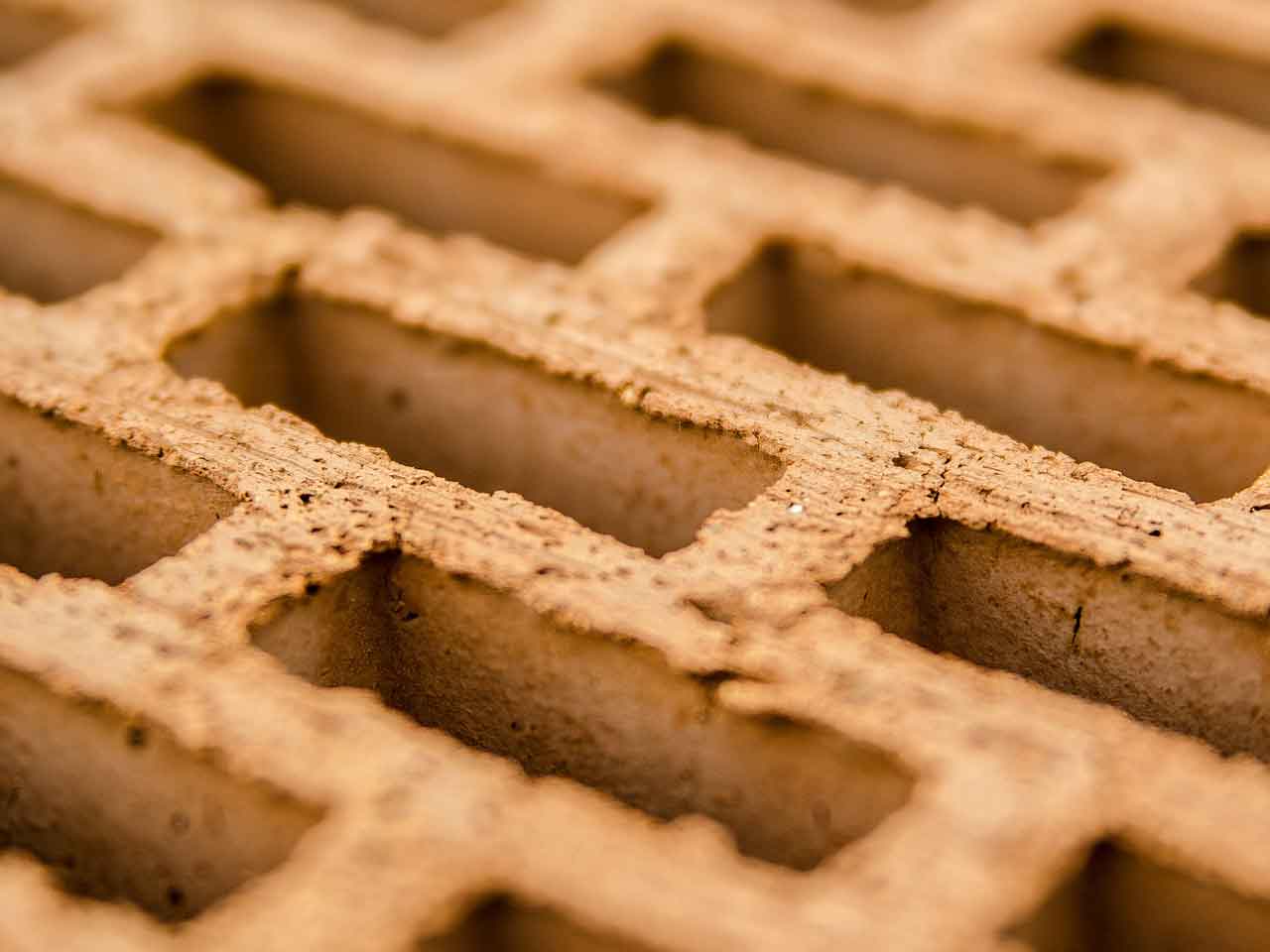

In the construction industry, machines and tools are used that generate waste material in the course of production, which can be as large as fine dust. Sanders, scarifiers, milling machines and shot peening machines are tools that inevitably produce large quantities of waste in the production of building materials.

For a construction industry, the timely removal of the large quantities of waste materials and fine dust produced during the processing of materials is a priority. These slow down production when they become a hindrance and at the same time endanger the health of workers, even if they are equipped with personal protective equipment.

The Sistem Air Pro central vacuum system is ideal for safely transporting waste material of various sizes, generated in the production of building materials, outside the building and collecting it in a way that facilitates its disposal and recovery. The correct disposal and recovery of waste is essential to ensure safety for both the environment and people.

This system can also be combined with Sistem Air Pro's Roll Flex motorised winder model, which has 20 metres of hose to reach anywhere in the plant, with a motor that allows it to be unwound and rewound without the need for return springs, and wall-mounted installation that avoids possible obstructions.

In addition, the industrial line can be combined with a cyclonic separator with which it will be possible to intercept over 98% of the dust sucked in and preserve the filter, cycles and maintenance costs.

Finally, the motors of the industrial line also provide adjustable suction power, in all conditions of use, to ensure an intelligent delivery that further optimises cleaning costs.

Construction is also responsible for 36% of global electricity consumption and 1/3 of global drinking water consumption.

The Circular Economy Report 2021 estimates annual savings of around €100 billion for Italian industries if circular economy management practices were adopted.

Not only wood shavings, but also the dust generated by the materials used in the various processes in carpentry workshops.

When micro-dust is not inert, there are several occupational diseases to which construction workers are exposed.

It is a partnership that goes back a long way, to 2008 to be precise, between Sistem Air and the company Al.fa. Impianti of Alberto Cusenza.

The impact of fine dust on production and operators.

Sistem Air Pro is capable of responding to all professional and industrial sector requests