WHO: Construction responsible for 39% of air pollution

Construction is also responsible for 36% of global electricity consumption and 1/3 of global drinking water consumption.

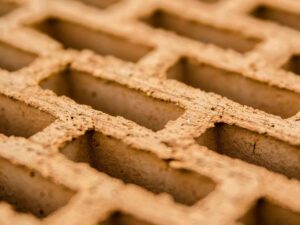

One of the problems associated with the production of bricks and cement is the production of dust, which is mainly generated during the grinding of raw materials.

Dust from the construction industry can be either coarse or fine dust. But while a person may immediately realise that he or she is exposed to coarse dust and can therefore remedy it, he or she does not realise that he or she is in contact with fine dust, which reaches the lungs almost undisturbed.

And, in this case, even in the least dangerous condition, with exposure to inert, non-water-soluble, low-toxicity dust, inflammatory processes of the respiratory tract can develop.

But when micro-dust is not inert, there are several occupational diseases to which construction workers are exposed. Among the most dangerous and frequent are those that damage the respiratory tract, such as chronic bronchial diseases, occupational bronchial asthma, lung cancer and silicosis.

Obviously, the health risk and pollutants to which the operator is exposed vary according to the work process involved, the type of equipment used and the material processed.

In particular, cement and some products used in construction contain silica stone and silica dust. The latter, if inhaled, lead to the formation of nodules where lung tissue heals. When the nodules become too large, breathing becomes difficult and serious health consequences can occur.

With regard to cement production in particular, another source of dust is the production kilns, whose emissions must be captured and properly treated.

In addition to accident risks, workers in the sector are therefore exposed to various occupational diseases. This is why it is necessary to take the necessary measures to prevent them from inhaling harmful micro-dust.

The use of an industrial vacuum cleaner, and in particular of a industrial central vacuum system, guarantees acoustic comfort and maximum performance against dust, dirt and all those substances that are harmful to health.

In this sector, the dust filtration class is a determining factor.

Sistem Air Pro's products have class M filters. A class that guarantees suitable filtration for the extraction of all dust that is harmful to health and with occupational exposure limit values (VLEP) ≥ 0.1 mg/m³.

Construction is also responsible for 36% of global electricity consumption and 1/3 of global drinking water consumption.

The Circular Economy Report 2021 estimates annual savings of around €100 billion for Italian industries if circular economy management practices were adopted.

Not only wood shavings, but also the dust generated by the materials used in the various processes in carpentry workshops.

When micro-dust is not inert, there are several occupational diseases to which construction workers are exposed.

It is a partnership that goes back a long way, to 2008 to be precise, between Sistem Air and the company Al.fa. Impianti of Alberto Cusenza.

The impact of fine dust on production and operators.

Sistem Air Pro is capable of responding to all professional and industrial sector requests