Protect your factory floor with the central vacuum system

Nonostante i capannoni siano “solitamente” spazi semplici da gestire, la loro pulizia spesso risulta essere più complicata del previsto.

For companies that produce and process dry feeds, or similar products such as cereals or flour, transporting the product to storage silos is a process fraught with pitfalls. These products are by nature very dusty and inevitably tend to soil the materials on which they are processed or clog the auger in the pipes that transport them to the storage silos.

Dust or small, uneven parts of the feed clog up and slow down production too often. This causes incalculable damage in terms of time, and therefore economic damage.

Only those who work in this sector know what it means to stop the production cycle at least once a day to clean the pipes where the clogged auger can no longer load the silo. Not to mention the machinery inside the plants which, if blocked, can pose a serious health risk to the operators who use them.

Wheeled vacuum cleaner or compressed air: two examples of cleaning systems that are not only sloppy, but also tiring to use. Unfortunately, these tools are commonly used in factories in the sector, but they are only a solution that may buffer the problem, but certainly does not eliminate it.

Compressed air, for example, moves the dust that is clogging the machinery but does not eliminate it, so it will come back later. Or, worse still, it is breathed in by the operators themselves.

A wheeled vacuum cleaner, on the other hand, which is difficult to transport, is not able to eliminate micro-dust as it has a vent inside the machine itself.

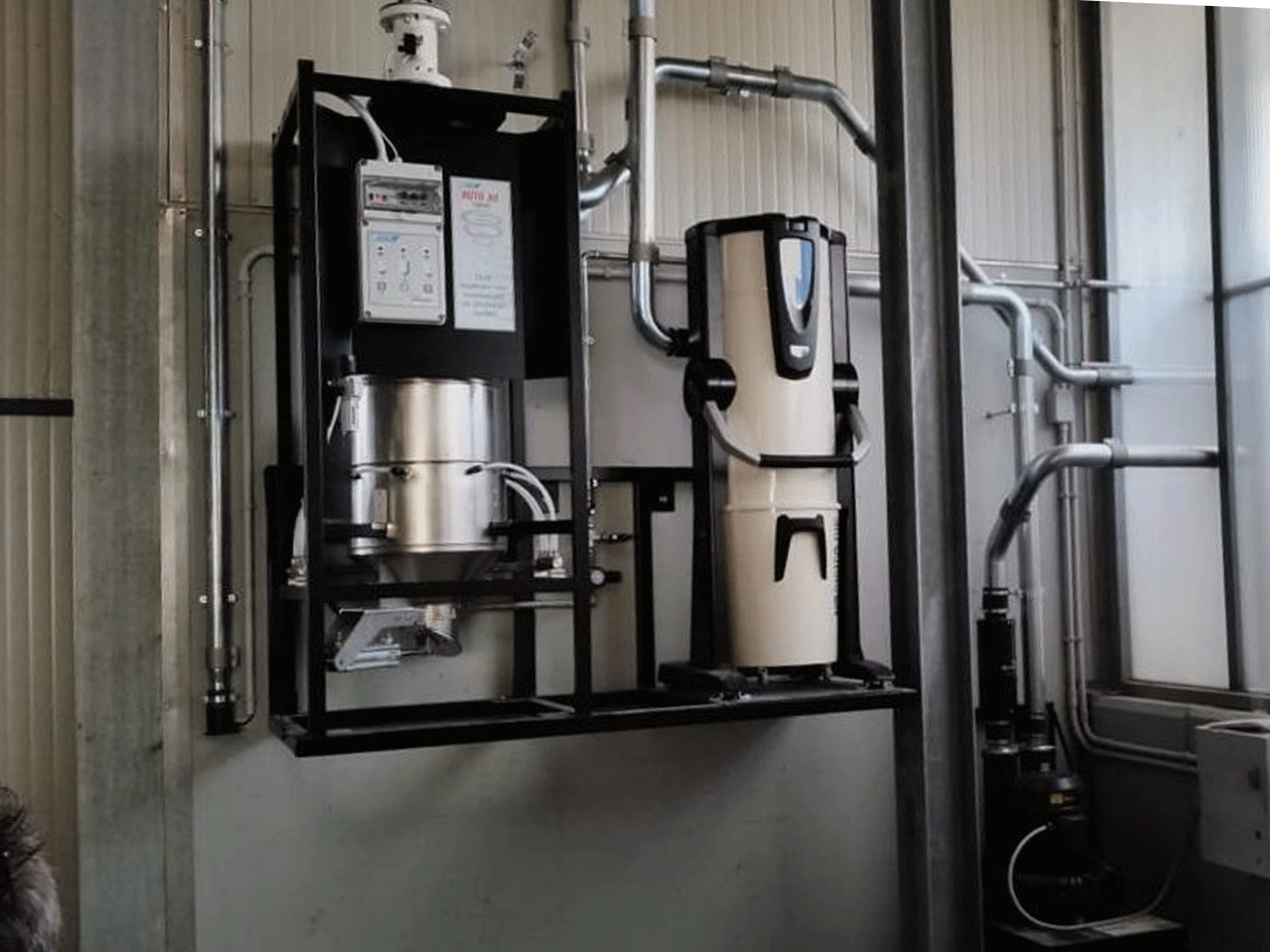

The Sistem Air Pro industrial central vacuum system is the ultimate solution for those working in this sector. With the possibility of installing the central vacuum unit at the desired point, in a designated room or outside the factory, the elimination of waste material, dust and micro-dust is guaranteed. In this way, machinery such as the pipes transporting the product to the silos are cleaned quickly and thoroughly.

Well-designed cleaning prevents daily dust interruptions. Furthermore, equipping the central vacuum system with a cyclonic separator and an automatic unloading system provides additional benefits.

If, on the one hand, the cyclonic separator preserves the filter of the central vacuum unit, reducing maintenance costs, on the other hand, an automatic unloading system allows large volumes of material to be handled completely independently. Material that can be recovered, reducing waste and optimising costs.

Nonostante i capannoni siano “solitamente” spazi semplici da gestire, la loro pulizia spesso risulta essere più complicata del previsto.

The reopenings and the return to normal life have revived consumption, but with such a demand that the production system cannot reorganise itself.

Whether in the food, manufacturing or automotive industries, to name but a few, suction of liquids is notoriously an obstacle.

The Circular Economy Report 2021 estimates annual savings of around €100 billion for Italian industries if circular economy management practices were adopted.

For companies producing and processing dry feed, or similar products such as cereals or flour, transporting the product to storage silos is a process fraught with pitfalls.

Even when you have cleaned a surface, dirt may remain hidden and unseen.

Sistem Air Pro is capable of responding to all professional and industrial sector requests