Industrial central vacuum systems Sistem Air Pro

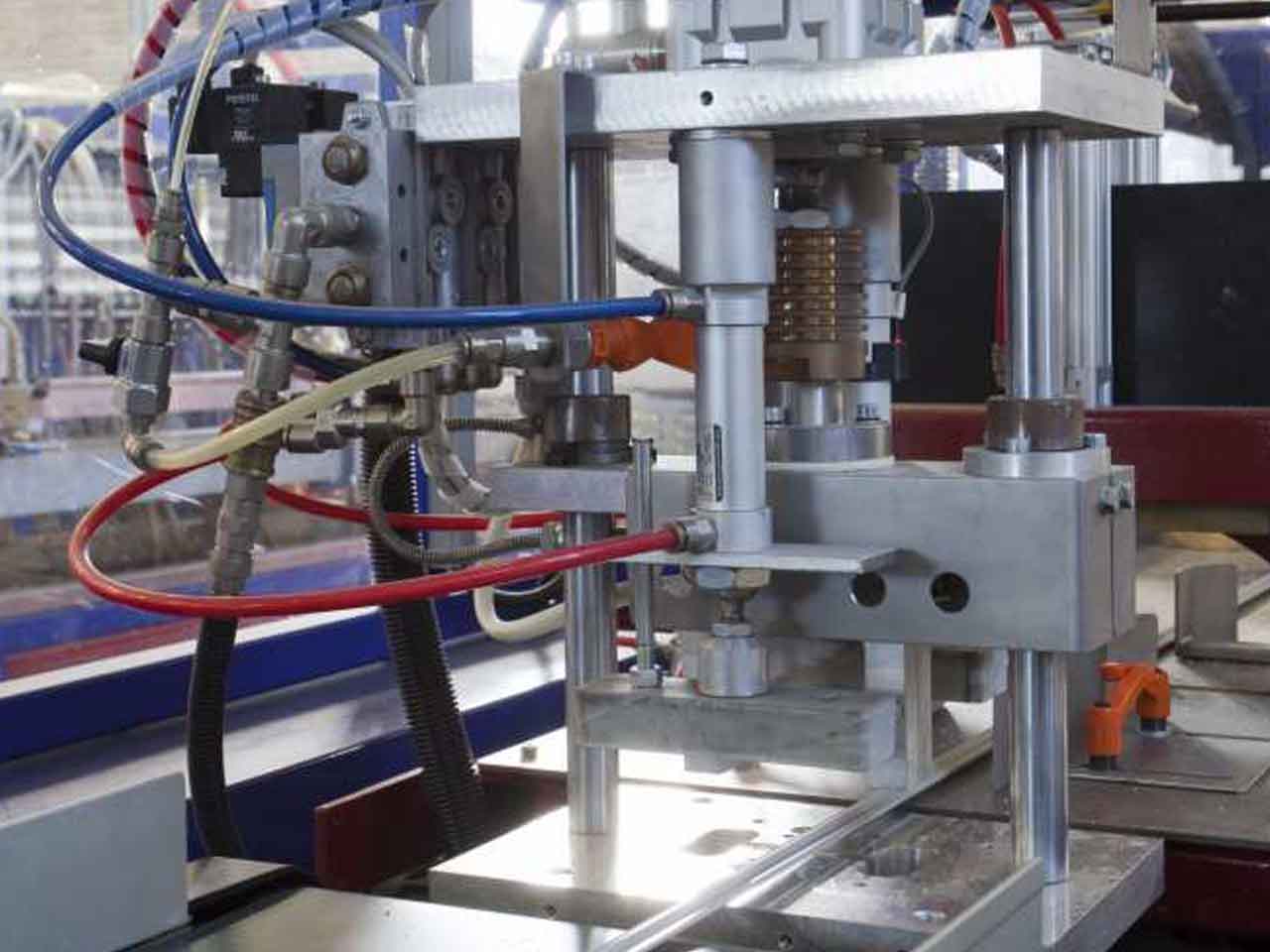

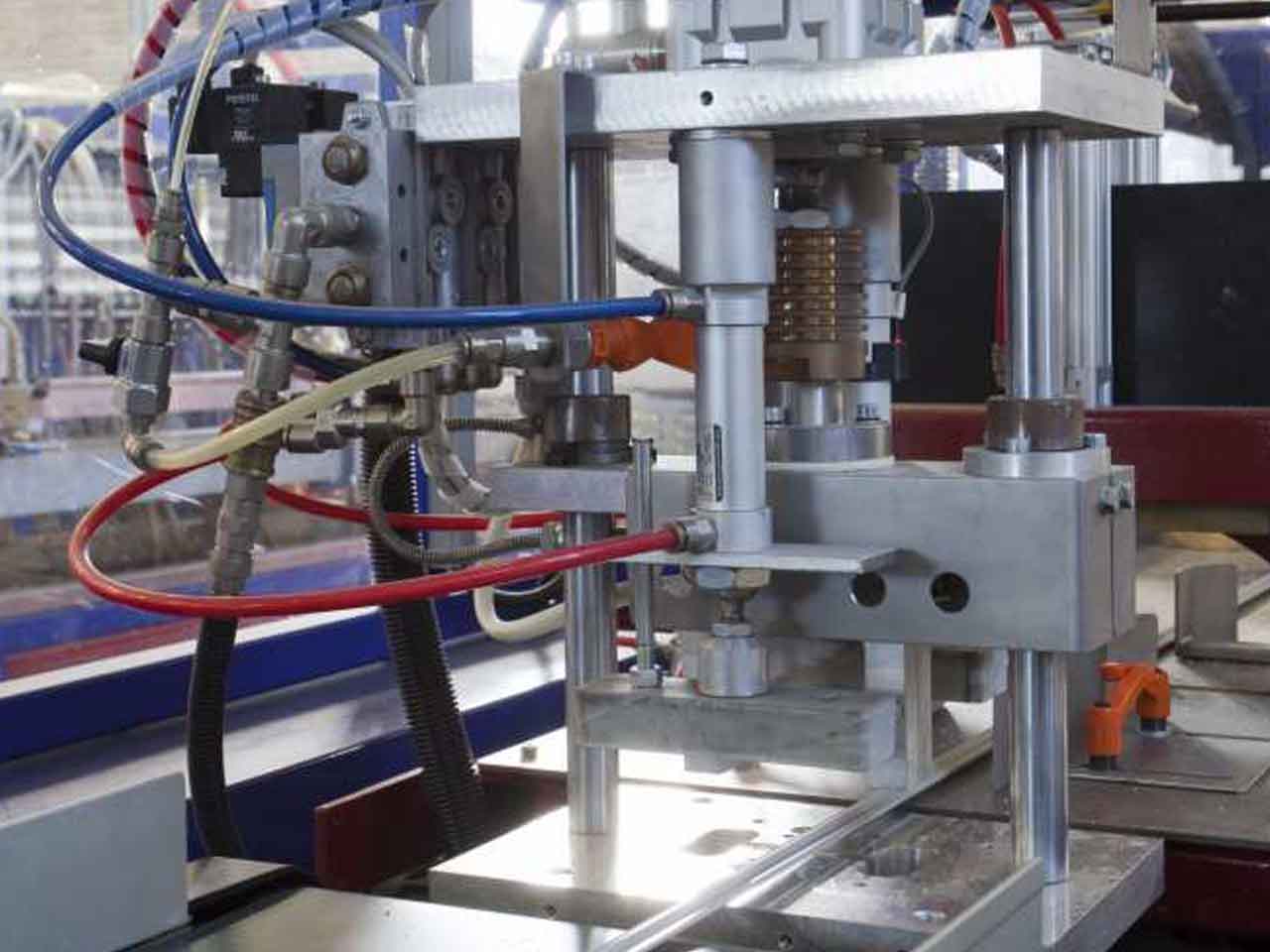

Sistem Air Pro designs and builds modular central vacuum systems capable of deep cleaning workplaces.

Plastics are made up of pure polymers or mixed with additives. It is usually said that synthetic polymers are inert and non-toxic, which is true, but the danger from dust, temperature or adjuvants must be considered. The main chemical agents, on the other hand, are: resins, polymers, any additives and all substances that may develop during hot work and combustion.

In particular, the critical phases of the work process are: purging operations, cleaning of moulds or presses, preparation (pelleting) of resins, weighing operations, addition of powder masters.

The sector's work processes are characterised by the different types of plastic materials used. In fact, depending on the plastic material used, the characteristics of the processes may be different, but also the additives used to confer particular properties may be different.

The working process in the plastics industry can be organised differently depending on the type of production, as well as the characteristics of the environment in which the activity is carried out. However, it is a process whose layout is relatively simple and there are plant standards that cannot be ignored.

Plastics processing involves exposure to particulate matter, i.e. to dust originating from raw materials during handling processes, with specific but also general toxicological effects linked to the mechanical irritation that dust exerts on tissues and the accumulation of fine dust in the lower respiratory tract.

Particularly affected by exposure to particulate matter is the inhalation route, although irritative effects may also develop on the skin and eye mucous membranes, especially in conditions that favour the release of molecules (e.g. perspiration on exposed skin, high environmental humidity). The toxicological risk proper occurs when the particle size of the particles allows entry into the deep respiratory tract.

In addition to any specific toxicological effects, the inhalation of hard-structured dusts (mineral dusts, some crystalline polymer dusts) or synthetic fibres can lead to the development of chronic pathologies and even tumours localised to the respiratory system, through an action that develops through a repeated series of inflammatory processes affecting the tissue on which the dusts or fibres are deposited, resulting in a series of transformations of the tissue to the point of compromising its functionality or disrupting its operating mechanisms.

Plastics processing involves exposure to particulate matter, i.e. to dust originating from raw materials during handling processes, with specific but also general toxicological effects linked to the mechanical irritation that dust exerts on tissues and the accumulation of fine dust in the lower respiratory tract.

Particularly affected by exposure to particulate matter is the inhalation route, although irritative effects may also develop on the skin and eye mucous membranes, especially in conditions that favour the release of molecules (e.g. perspiration on exposed skin, high environmental humidity). The toxicological risk proper occurs when the particle size of the particles allows entry into the deep respiratory tract.

In addition to any specific toxicological effects, the inhalation of hard-structured dusts (mineral dusts, some crystalline polymer dusts) or synthetic fibres can lead to the development of chronic pathologies and even tumours localised to the respiratory system, through an action that develops through a repeated series of inflammatory processes affecting the tissue on which the dusts or fibres are deposited, resulting in a series of transformations of the tissue to the point of compromising its functionality or disrupting its operating mechanisms.

Because of the above, extraction, ventilation and air exchange are environmental necessities.

The Sistem Air Pro industrial central vacuum system, thanks to its modularity, offers a solution capable of adapting to any working environment and able to remove micro-dust in depth, protecting the health of the operators.

In addition to protecting operators from accidental slipping on plastic granules, the central vacuum system allows the recovery of the suctioned material so that it can be returned to the production line, thus generating an economic return.

Sistem Air Pro designs and builds modular central vacuum systems capable of deep cleaning workplaces.

Nonostante i capannoni siano “solitamente” spazi semplici da gestire, la loro pulizia spesso risulta essere più complicata del previsto.

The reopenings and the return to normal life have revived consumption, but with such a demand that the production system cannot reorganise itself.

Lorenzo Valerio owns a paint factory, where he treats both wood and metal, and in his business the difficult relationship with dust and waste is a constant.

Glass, even in its derived forms such as glass-fibre reinforced plastics, is an increasingly popular material because of its strength, impermeability and lightness.

Whether in the food, manufacturing or automotive industries, to name but a few, suction of liquids is notoriously an obstacle.

Sistem Air Pro is capable of responding to all professional and industrial sector requests